So recently I let my ADD get the better of me, and much to my surprise and pleasure, the results were incredible. Finally able to spend a few unadulterated hours with my arboreal love, I found myself scratching my head trying to figure out where to pick back up and what most needed work. As I soon discovered, I had no desire to spend my few precious hours sanding away on the soundbox trying to get the sides prepped for gluing the back purfling. Instead I decided to work on a key, yet hidden, aesthetic of the guitar - the soundbox label.

The soundbox label is generally very simplistic and utilitarian. Its most basic function is to denote the manufacturer, model, serial number, and country of origin. Some higher end manufacturers and home-spun luthiers, however, use the soundbox label as another means to distinguish themselves and their creations. For me, it's the icing on the cake - A chance to make an otherwise ubiquitous musical instrument truly one of a kind. As such, I did not want to rush headlong into such a meaningful and delicate operation. Time to call in the big guns - and I do mean BIG!

Meet Sarah - artist, professional student, missionary, wood sprite, adventurer, boater extraordinaire, amazonian giantess... And fortunately (or unfortunately [jk]) for me - sister-in-law. Yes folks, that is a fully mature 400-lb bighorn sheep, dwarfed as it were by Sarah's 8'2" height;-). Ok so maybe I exaggerate a smidgen, but only just!

Anyway, getting back to the point - Sarah, here, is an incredible visual artist and it was her input that birthed the inspiration for my first guitar's soundbox label. So if you don't like it, you can blame her! One day I was painfully trying to pull together the various tailored aspects of the guitar in addition to my father's personality and preferences in an effort to design a suitable label. To be honest, I was spinning in circles getting nowhere. Gigantor, uh I mean Sarah was looking over my shoulder shaking her head when I finally threw my hands up and asked her for help. She immediately jumped at the opportunity to keep me from a fate worse than death - aesthetic ignominy!

To me it was an equation, something to solve. Mix together all the inputs and adjust the variables until you reach the correct solution. To Sarah, hmmm, to Sarah..... well, to Sarah it was anything but an equation. I cannot begin to understand how the mind of a woman works, let alone that of a female artist - so suffice it to say she did her magic and so a masterpiece was born.

Question: Of what principle material is a guitar made?

Answer: Wood, and in my case, bloody, gory wood... (sharp implements and an impatient, distractible nature do not mix well!)

Question: What primarily produces each guitar's unique tonal quality?

Answer: The unique combination and grades of the woods used in its construction.

Question: What is most central to a guitar's identity and overall quality?

Answer: The wood!

So it all boils down to the wood, and what is wood? Dead and seasoned trees. And what defines my dad the most, apart from his servants heart and identity in Christ? His passion for the wild spaces of our earth, the deep forest sanctuaries, the quiet alpine glades, the timeless Appalachian expanses. So what better to bind the musician and the instrument together than an element fundamental to them both. Just as a seed falls to the ground with the hope of springing forth into life, finding fertile soil and plentiful sun and water, it will venture into being and only the Lord know the plans He has for the seedling - so too my dad's guitar.

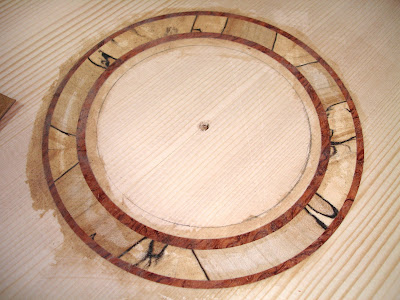

Without further ado, I give you my falling seed - Verdani Guitars Model 14-000+, No. 001.

The soundbox label is generally very simplistic and utilitarian. Its most basic function is to denote the manufacturer, model, serial number, and country of origin. Some higher end manufacturers and home-spun luthiers, however, use the soundbox label as another means to distinguish themselves and their creations. For me, it's the icing on the cake - A chance to make an otherwise ubiquitous musical instrument truly one of a kind. As such, I did not want to rush headlong into such a meaningful and delicate operation. Time to call in the big guns - and I do mean BIG!

Meet Sarah - artist, professional student, missionary, wood sprite, adventurer, boater extraordinaire, amazonian giantess... And fortunately (or unfortunately [jk]) for me - sister-in-law. Yes folks, that is a fully mature 400-lb bighorn sheep, dwarfed as it were by Sarah's 8'2" height;-). Ok so maybe I exaggerate a smidgen, but only just!

Anyway, getting back to the point - Sarah, here, is an incredible visual artist and it was her input that birthed the inspiration for my first guitar's soundbox label. So if you don't like it, you can blame her! One day I was painfully trying to pull together the various tailored aspects of the guitar in addition to my father's personality and preferences in an effort to design a suitable label. To be honest, I was spinning in circles getting nowhere. Gigantor, uh I mean Sarah was looking over my shoulder shaking her head when I finally threw my hands up and asked her for help. She immediately jumped at the opportunity to keep me from a fate worse than death - aesthetic ignominy!

To me it was an equation, something to solve. Mix together all the inputs and adjust the variables until you reach the correct solution. To Sarah, hmmm, to Sarah..... well, to Sarah it was anything but an equation. I cannot begin to understand how the mind of a woman works, let alone that of a female artist - so suffice it to say she did her magic and so a masterpiece was born.

Question: Of what principle material is a guitar made?

Answer: Wood, and in my case, bloody, gory wood... (sharp implements and an impatient, distractible nature do not mix well!)

Question: What primarily produces each guitar's unique tonal quality?

Answer: The unique combination and grades of the woods used in its construction.

Question: What is most central to a guitar's identity and overall quality?

Answer: The wood!

So it all boils down to the wood, and what is wood? Dead and seasoned trees. And what defines my dad the most, apart from his servants heart and identity in Christ? His passion for the wild spaces of our earth, the deep forest sanctuaries, the quiet alpine glades, the timeless Appalachian expanses. So what better to bind the musician and the instrument together than an element fundamental to them both. Just as a seed falls to the ground with the hope of springing forth into life, finding fertile soil and plentiful sun and water, it will venture into being and only the Lord know the plans He has for the seedling - so too my dad's guitar.

Without further ado, I give you my falling seed - Verdani Guitars Model 14-000+, No. 001.

And yes, she was a willing victim...